SS Tube Mill Rolls

SS Tube Mill Rolls Specification

- Type

- Tube Mill Roll

- Material

- Stainless steel

- Application

- Tube / Pipe Manufacturing

- Height

- 609.6 - 762 Millimeter (mm)

- Product Type

- Mill Rolls

- Weight

- 10-20 Kilograms (kg)

- Color

- Silver

- Weight (kg)

- 10-20

- Hardness

- 50-60 HRC

- Surface Finish

- Polished

- Usage

- Industrial Pipe & Tube Rolling Mills

- Tolerance

- ±0.05 mm

- Corrosion Resistance

- High

- Height (mm)

- 609.6 - 762

- Diameter Range (mm)

- 50-300

SS Tube Mill Rolls Trade Information

- Minimum Order Quantity

- 10 Sets

- Supply Ability

- 1 Set Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

About SS Tube Mill Rolls

High-Grade SS Tube Mill Rolls by Sharp Edge Reliable, Durable, and Efficient Tooling Solutions

At Sharp Edge, we embarked on our journey as a trustworthy manufacturer and exporter of high-quality equipment for the tube and pipe industry. With a strong commitment to excellence, we are proud to offer high-grade SS Tube Mill Rolls designed to meet the diverse needs of pipe manufacturers worldwide. These rolls are crafted using premium stainless steel and advanced manufacturing techniques, ensuring superior performance, durability, and precision across various tube mill applications.

Why Choose Sharp Edge SS Tube Mill Rolls?

Our SS Tube Mill Rolls are engineered to offer exceptional quality and performance. Manufactured by our expert team of professionals using top-grade stainless steel, these rolls are designed to handle multiple operations, including roll bending, roll forming, and profile creation. Whether youre involved in pipe production, metalworking, or other industrial processes, Sharp Edge SS Tube Mill Rolls provide the precision and reliability required for consistent results.

Key Features of Sharp Edge SS Tube Mill Rolls:

-

Rust-Proof Structure for Longevity

Our SS Tube Mill Rolls feature a corrosion-resistant design, ensuring they remain rust-free even in demanding industrial environments. The use of high-quality stainless steel makes these rolls ideal for long-term use, offering enhanced durability and preventing wear from exposure to moisture or harsh conditions. -

High Durability for Heavy-Duty Applications

Built to withstand the rigors of continuous use, our SS Tube Mill Rolls are engineered for superior durability. These rolls maintain optimal performance over time, reducing the need for frequent replacements and minimizing downtime, making them a cost-effective solution for your production processes. -

Low Maintenance for Increased Efficiency

Designed to require minimal upkeep, our SS Tube Mill Rolls help reduce maintenance time and costs, allowing your operations to run smoothly and efficiently. Their low maintenance design ensures that you can focus on productivity without worrying about constant adjustments or repairs.

Manufactured to Industry Standards

At Sharp Edge, we follow strict quality control measures throughout the manufacturing process to ensure our SS Tube Mill Rolls meet the highest industry standards. Our skilled professionals utilize cutting-edge techniques and the finest materials to produce rolls that deliver precision and consistent performance in every application. Whether youre engaged in high-volume production or specialized projects, you can trust our SS Tube Mill Rolls to offer accurate results and long-lasting durability.

Applications of SS Tube Mill Rolls

Our SS Tube Mill Rolls are widely used in various industries, particularly in the pipe and tube manufacturing sector. These rolls enable multiple operations, including:

- Roll Bending: Achieving smooth and accurate bending of tubes and pipes, ensuring precise shaping for various applications.

- Roll Forming: Creating seamless shapes and profiles, perfect for industries requiring consistent and uniform results.

- Profile Creation: Customizing tube profiles to meet specific design and production requirements.

Benefits of Using Sharp Edge SS Tube Mill Rolls:

-

Enhanced Corrosion Resistance

The stainless steel construction of our rolls ensures exceptional resistance to rust and corrosion, making them perfect for operations in environments where moisture and exposure to corrosive materials are common. -

Cost-Effective Solution

With their high durability and low maintenance requirements, our SS Tube Mill Rolls offer a cost-effective solution for manufacturers. They provide long-lasting performance, reducing the frequency of roll replacements and minimizing production downtime. -

Precision and Efficiency

Our SS Tube Mill Rolls are designed for precision and efficiency in various operations. Whether youre performing roll forming, bending, or creating custom profiles, these rolls ensure consistent, high-quality results, improving overall production efficiency.

Available at Competitive Prices

Sharp Edge is dedicated to offering high-quality products at market-leading prices. Our SS Tube Mill Rolls are not only crafted to meet the most demanding production requirements but are also available at competitive rates, making them an excellent investment for companies looking to improve their production processes without breaking their budget.

Why Trust Sharp Edge?

With years of expertise in manufacturing and exporting tube mill equipment, Sharp Edge has established a strong reputation for delivering quality. Our commitment to excellence ensures that every product we offer, including our SS Tube Mill Rolls, is designed to meet the rigorous standards of the industry. Our customer-first approach guarantees that you receive the best tooling solutions tailored to your specific needs.

Order Sharp Edge SS Tube Mill Rolls Today

Elevate your tube and pipe production processes with Sharp Edge SS Tube Mill Rolls. Designed for longevity, precision, and efficiency, these rolls will help enhance your operations, reduce costs, and ensure superior product quality. Contact us today to learn more about our SS Tube Mill Rolls or place an order to take your production to the next level.

By choosing Sharp Edge, you are investing in advanced tooling solutions that offer exceptional durability, minimal maintenance, and unmatched performance, ensuring your success in the tube mill industry.

Exceptional Corrosion Resistance

Constructed from premium stainless steel, these tube mill rolls deliver outstanding corrosion resistance, making them suitable for demanding manufacturing environments. The polished surface finish further enhances their longevity and maintains performance, minimizing maintenance needs even in harsh conditions.

Precision Manufacturing for Optimal Output

With a diameter range of 50300 mm and a tolerance of 0.05 mm, these rolls ensure consistent tube and pipe formation. Their high hardness of 5060 HRC provides excellent wear resistance, sustaining precise shaping and reliable operation in intensive industrial use.

Versatile Usage Across Industrial Mills

SS Tube Mill Rolls are engineered for use in various tube and pipe manufacturing mills. Their robust build and superior surface finish allow seamless integration into different rolling setups, supporting efficient and high-quality tube production processes for both small and large-scale operations.

FAQs of SS Tube Mill Rolls:

Q: How are SS Tube Mill Rolls installed in tube and pipe manufacturing mills?

A: SS Tube Mill Rolls are mounted onto rolling mill machines according to mill specifications. Installation requires precise alignment and secure fastening to ensure smooth and accurate tube formation during operation.Q: What makes these tube mill rolls beneficial for industrial applications?

A: Their high corrosion resistance, polished finish, and hardness of 5060 HRC contribute to long life and minimal wear. This results in reduced downtime and enhanced quality in tube and pipe production, improving overall manufacturing efficiency.Q: When should these rolls be replaced in a tube rolling mill?

A: Replacement is advised when visible wear, reduced shaping precision, or surface damage occur. Regular inspection based on production volume and working conditions helps determine the optimal replacement interval for maintaining high-quality output.Q: Where are SS Tube Mill Rolls most commonly utilized?

A: These rolls are extensively used in industrial pipe and tube rolling mills, especially in facilities focused on stainless steel tube and pipe manufacturing. They are supplied throughout India by various distributors, manufacturers, and exporters.Q: What process is followed to manufacture SS Tube Mill Rolls?

A: The manufacturing process involves precision forging or machining of stainless steel, followed by heat treatment to achieve 5060 HRC hardness. Polishing ensures a smooth surface finish, while rigorous quality checks guarantee dimensional accuracy and tolerance within 0.05 mm.Q: How does the rolls polished surface enhance its performance?

A: The polished surface reduces friction during tube formation, minimizing oxidation and wear. It lessens buildup of manufacturing residues, thereby maintaining consistent product quality and prolonging the rolls service life.Q: Can these tube mill rolls be customized to specific sizes or requirements?

A: Yes, manufacturers can tailor these rolls to fit particular industrial needs, including adjustments in diameter, height, and tolerance, ensuring compatibility with varied tube and pipe rolling mill designs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tube Mill Rolls Category

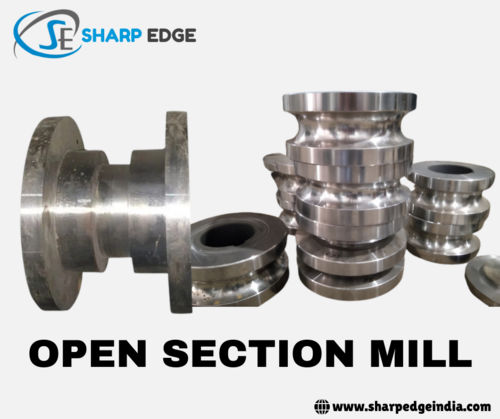

Open Section Mill

Minimum Order Quantity : 10 Sets

Height : as per demand Inch (in)

Material : Stainless Steel

Color : silver

Application : Metal Shaping & Forming

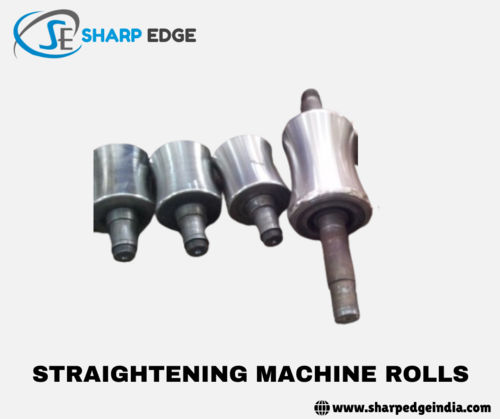

Straightening Machine Rolls

Minimum Order Quantity : 10 Sets

Height : 609.6 762 Millimeter (mm)

Material : Stainless steel

Color : Silver

Application : Straightening Machines

Product Type : Machine Rolls

MS Tube Mill Rolls

Minimum Order Quantity : 10 Sets

Height : 609.6 762 Millimeter (mm)

Material : Stainless steel

Color : Silver

Product Type : Mill Rolls

GST : 06AETPV3586R2Z2

|

|

SHARP EDGE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry