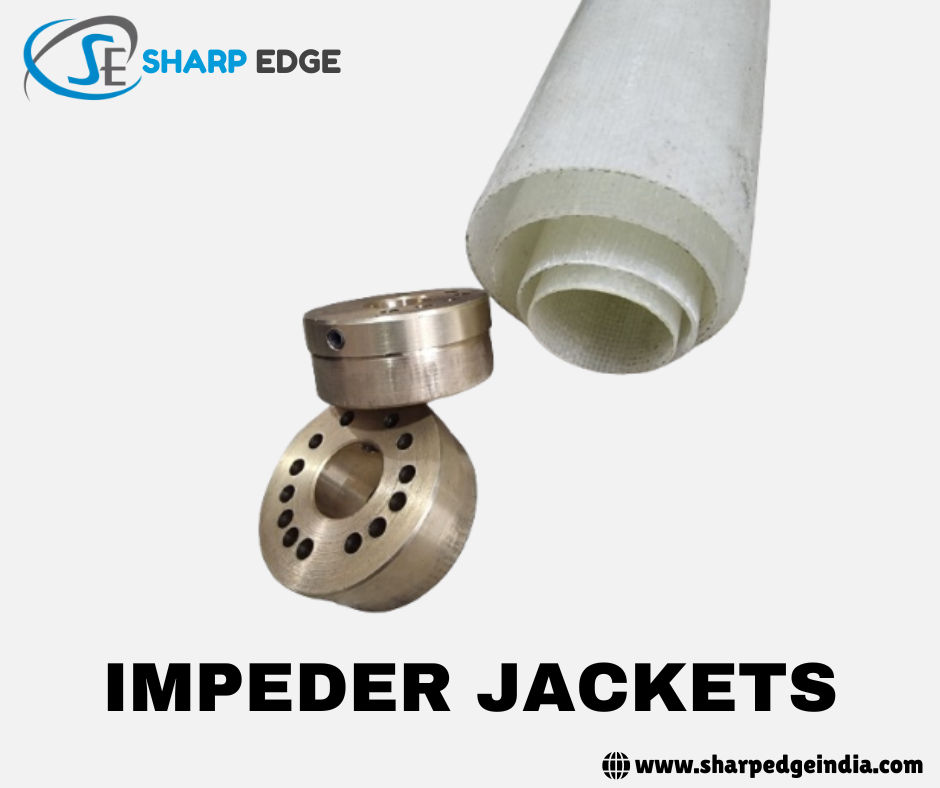

Impeder Jackets

Price 10000.00 INR/ Set

Impeder Jackets Specification

- Features

- High Quality

- Product Type

- Machine Parts

- Material

- Stainless steel

- Voltage

- 220-480 Volt (v)

- Weight

- 100 Grams (g)

- Color

- white

- Warranty

- 6 months to 1 year

Impeder Jackets Trade Information

- Minimum Order Quantity

- 10 Sets

- Supply Ability

- 1 Set Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

About Impeder Jackets

High-Quality Impeder Jackets by Sharp Edge ï Durable, Precise, and Efficient Solutions for Industrial Applications

Established in 2010, Sharp Edge has become a trusted name in the manufacturing and supply of industrial equipment. Among our wide range of products, our Impeder Jackets stand out for their exceptional quality, durability, and reliability. These jackets are meticulously crafted under the supervision of our skilled professionals, using high-grade materials and advanced production techniques to ensure they meet the highest industry standards. Available in a variety of sizes to suit diverse applications, our Impeder Jackets are designed to deliver optimum performance in the chassis of impeder systems.

Why Choose Sharp Edge Impeder Jackets?

Sharp Edge has built its reputation by providing high-quality products that cater to the unique demands of the industrial sector. Our Impeder Jackets are no exception. Manufactured with precision and care, these jackets offer superior protection and enhanced functionality for impeder systems, ensuring that your production processes run smoothly and efficiently. By focusing on durability, strength, and cost-effectiveness, we deliver a product that exceeds expectations and provides lasting value to our customers.

Key Features of Sharp Edge Impeder Jackets:

-

Perfect Finish for Smooth Operation

Each Impeder Jacket is designed with a seamless, flawless finish, ensuring a perfect fit in the impeder chassis. This smooth finish not only improves the aesthetic quality but also contributes to the efficient performance of the equipment, reducing the chances of operational errors and enhancing productivity. -

Enhanced Service Life for Long-Term Use

Our Impeder Jackets are built to last. Using high-quality, durable materials, these jackets are resistant to wear and tear, making them ideal for long-term industrial use. This extended service life helps minimize the need for frequent replacements, ensuring that your operations can continue without unnecessary downtime or interruptions. -

Optimum Strength for Reliable Performance

Designed to withstand the demands of industrial environments, our Impeder Jackets offer optimum strength. This robust construction ensures that the jackets can endure the stresses of regular use, providing consistent performance in high-frequency welding and other demanding applications. Their strength makes them ideal for heavy-duty use in tube and pipe manufacturing processes.

Manufactured to Industry Standards

At Sharp Edge, we take pride in following strict quality control processes throughout the production of our Impeder Jackets. Every jacket is manufactured to meet industry-leading standards, ensuring reliability and precision in every product. Our team of skilled professionals utilizes the latest techniques to create jackets that perform flawlessly in impeder systems, offering consistent results in even the most challenging industrial applications.

Applications of Impeder Jackets

Impeder Jackets play a crucial role in impeder systems, providing protection and stability in various industrial processes. These jackets are specifically designed to work in the chassis of the impeder, ensuring smooth and efficient operation during high-frequency welding and other production activities. Their high durability and precision make them suitable for industries such as:

- Automotive Manufacturing

- Construction

- Metal Fabrication

- Pipe and Tube Production

By investing in Sharp Edgeïs Impeder Jackets, manufacturers can improve the efficiency of their production lines, ensuring superior-quality results and increased operational efficiency.

Benefits of Using Sharp Edge Impeder Jackets:

-

Improved Equipment Efficiency

Sharp Edge Impeder Jackets are designed to enhance the overall efficiency of impeder systems. By offering a perfect fit and robust protection, these jackets ensure that the impeder performs optimally, resulting in better production outcomes and increased operational speed. -

Durable and Long-Lasting

Built for long-term use, our Impeder Jackets are highly resistant to damage and wear. Their durable construction ensures that they can handle the rigors of industrial use, reducing the need for frequent repairs or replacements and minimizing operational costs over time. -

Cost-Effective Solution

Offering a combination of high performance and low maintenance, our Impeder Jackets provide a cost-effective solution for industrial manufacturers. With their extended service life and affordable pricing, they are an excellent investment for companies looking to optimize their production processes without incurring excessive costs.

Custom Sizes and Competitive Pricing

Understanding the diverse needs of our clients, Sharp Edge offers Impeder Jackets in a wide range of sizes, ensuring that each product is tailored to fit your specific requirements. Our goal is to provide the perfect solution for your production needs, whether you're involved in high-frequency welding or other pipe and tube manufacturing processes. In addition, we are committed to offering our products at competitive, industry-leading prices, making sure that you get the best value for your investment.

Why Sharp Edge?

Since our inception in 2010, Sharp Edge has been dedicated to delivering high-performance industrial equipment that meets the needs of a rapidly evolving market. With a focus on quality, durability, and customer satisfaction, we have become a trusted partner for manufacturers across a wide range of industries. Our expertise and commitment to excellence ensure that every product we deliver, including our Impeder Jackets, meets the highest standards of performance and reliability.

Order Sharp Edge Impeder Jackets Today

If you are looking for durable, high-quality Impeder Jackets that offer optimal performance and extended service life, look no further than Sharp Edge. Our products are designed to help you maximize the efficiency of your industrial operations, reduce downtime, and minimize costs. Contact us today to learn more about our Impeder Jackets or to place an order for custom sizes. Trust Sharp Edge to provide the reliable, cost-effective solutions your business needs to excel in the competitive industrial market.

By choosing Sharp Edge Impeder Jackets, you are investing in a product that combines precision engineering, high-quality materials, and affordable pricing to deliver unmatched performance and durability in your production processes.

| OD SIZE OF EPOXY BODY | |

| 10 mm * 200 mm | 30 mm * 200 mm |

| 12 mm * 200 mm | 32 mm * 200 mm |

| 14 mm * 200 mm | 34 mm * 200 mm |

| 16 mm * 200 mm | 36 mm * 200 mm |

| 18 mm * 200 mm | 38 mm * 200 mm |

| 20 mm * 200 mm | 40 mm * 200 mm |

| 22 mm * 200 mm | 42 mm * 200 mm |

| 24 mm * 200 mm | 44 mm * 200 mm |

| 26 mm * 200 mm | 46 mm * 200 mm |

| 28 mm * 200 mm | 48 mm * 200 mm |

| 50 mm * 200 mm | |

Lightweight & Durable Construction

Despite weighing only 100 grams, Impeder Jackets offer sturdy protection and longevity, making them perfect for demanding environments. The stainless steel material guarantees resistance to wear and prolongs equipment life.

Reliable Voltage Operation

Designed to support a wide voltage range from 220 to 480 volts, these jackets integrate seamlessly with various industrial setups. This flexibility ensures safety and adaptability for diverse electrical requirements.

Comprehensive Warranty Coverage

Each Impeder Jacket comes with a warranty spanning from 6 months up to 1 year. This coverage affirms product quality and provides assurance for your investment, reducing maintenance costs.

FAQs of Impeder Jackets:

Q: How do I install an Impeder Jacket for optimal performance?

A: To install an Impeder Jacket, ensure that the surface is clean and dry. Place the jacket securely around the intended component, ensuring full coverage and firm attachment. For best results, follow the manufacturers detailed installation guidelines.Q: What are the primary benefits of using stainless steel Impeder Jackets?

A: The main advantages include high durability, excellent corrosion resistance, lightweight design, and effective insulation. Stainless steel construction ensures a longer product lifespan and consistent performance in varying industrial conditions.Q: When should I replace my Impeder Jacket?

A: Its advisable to inspect your Impeder Jacket regularly. Replace it if you notice significant wear, reduced insulation effectiveness, or after the warranty period of 6 months to 1 year, depending on usage and environment.Q: Where can I purchase authentic Impeder Jackets in India?

A: You can buy genuine Impeder Jackets directly from authorized distributors, exporters, manufacturers, or suppliers within India, ensuring product authenticity and access to warranty support.Q: What process ensures the high quality of these jackets?

A: Each Impeder Jacket undergoes a thorough manufacturing process using premium stainless steel and strict quality controls. This process guarantees high performance, uniformity, and adherence to industrial standards.Q: How do Impeder Jackets handle voltage ranges between 220 and 480 volts?

A: Designed for versatility, Impeder Jackets are engineered to operate seamlessly within 220-480 volts, providing reliable insulation and safety for a variety of electrical setups and industrial environments.Q: What makes these jackets suitable for export and distribution?

A: Their robust quality, compliance with international standards, and reliable performance make Impeder Jackets ideal for distribution and export, meeting the expectations of global industrial markets.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Impeder Jackets and Impeder Lines Category

Impeder Lines

Price 10000.00 INR / Set

Minimum Order Quantity : 10 Sets

Color : Silver

Product Type : Machine Parts

Voltage : .220480 Volt (v)

Material : Stainless steel

GST : 06AETPV3586R2Z2

|

|

SHARP EDGE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry